Compressive strength

Materials used for structural purposes are usually classified according to their resistance to basic stresses such as compression, tension and shear.

Compression is a force that pushes the particles of a material closer together. For example, when a column supports a load, it is under compression and its height shortens, albeit often imperceivably. The opposite is tensile force which tends to elongate a material.

All materials can, to a certain degree, withstand compressive forces before they fail and it is at this point that compressive strength is measured. Therefore, the compressive strength of a material is usually stated as the maximum compression that the material can stand before failure.

Materials which can resist high, applied compressive forces before failure are said to have high compressive strengths.

Some materials are better than others at withstanding compression before failure occurs. Steel can withstand relatively high compressive forces. Other materials, such as concrete and ceramics, typically show much higher compressive strengths than tensile strengths. Depending on the material, failure can comprise fracture at the compressive strength limit or irreversible deformation.

[edit] Measuring compressive strength

It is possible to measure precisely the compressive strength of materials by conducting a compressive test under carefully controlled conditions using a universal testing machine. This can typically have testing capacities of up to 53 mega Newtons (MN) which is equal to a 5,404 ton force.

In building construction, testing the compressive strength of concrete is usually undertaken at different stages after it has been poured in order to allow sufficient time for strength development (eg after 28 days). Typically, a cube (or cylinder) of concrete is used as a test specimen, ensuring that the top and bottom surfaces are flat and parallel, and that both faces are a perfect cross-section, ie, at right angles to the vertical axis of the cube.

A compressive force is applied to the specimen gradually by the testing mechanism. Measuring the compressive strength using this method requires:

- The cross-sectional area of one of the cube’s faces, top or bottom (they should be identical), and

- The compressive force applied at the time of failure (defined as permanent deformation - ie an inability to assume its former shape once the compressive force is removed).

Once these measurements are available, the compressive strength (C or σc) can be calculated as:

[edit] C = F/A

where F is the maximum force (load) applied at the point of failure and A is the cross-sectional area of the specimen before the force was applied. It can be expressed in terms of N/m² or Pascals (where 1 Pascal (Pa) = 1 N/m²).

It is sometimes difficult to measure the compressive strength of ductile metals, such as mild steel, which have high compressive strengths. This is due to the failure mode of such materials. Typically, under a compressive load, mild steel deforms elastically up to a point; this is followed by plastic deformation and ultimately the specimen may be flattened without significant evidence of fracture. It can therefore be difficult to measure the precise point of compressive failure. For this reason, it is more common to quote the tensile strength of mild steel which is easier to obtain; as its tensile strength is always lower than its compressive strength, it can be used as the basis for calculations.

[edit] Related articles on Designing Buildings

- Arch.

- Barrel vault.

- Compressive strength of timber lattice columns for low-rise construction.

- Concrete.

- Dome.

- Elements of structure in buildings

- Engineer.

- Flying buttress.

- Mass concrete.

- Steel.

- Structural engineer.

- Structural principles.

- Substructure.

- Superstructure.

- Tower.

- Tensile strength.

- Tension.

- Types of structure.

- Voussoir.

Featured articles and news

CLC and BSR process map for HRB approvals

One of the initial outputs of their weekly BSR meetings.

Building Safety Levy technical consultation response

Details of the planned levy now due in 2026.

Great British Energy install solar on school and NHS sites

200 schools and 200 NHS sites to get solar systems, as first project of the newly formed government initiative.

600 million for 60,000 more skilled construction workers

Announced by Treasury ahead of the Spring Statement.

The restoration of the novelist’s birthplace in Eastwood.

Life Critical Fire Safety External Wall System LCFS EWS

Breaking down what is meant by this now often used term.

PAC report on the Remediation of Dangerous Cladding

Recommendations on workforce, transparency, support, insurance, funding, fraud and mismanagement.

New towns, expanded settlements and housing delivery

Modular inquiry asks if new towns and expanded settlements are an effective means of delivering housing.

Building Engineering Business Survey Q1 2025

Survey shows growth remains flat as skill shortages and volatile pricing persist.

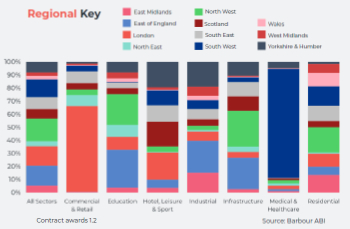

Construction contract awards remain buoyant

Infrastructure up but residential struggles.

Home builders call for suspension of Building Safety Levy

HBF with over 100 home builders write to the Chancellor.

CIOB Apprentice of the Year 2024/2025

CIOB names James Monk a quantity surveyor from Cambridge as the winner.

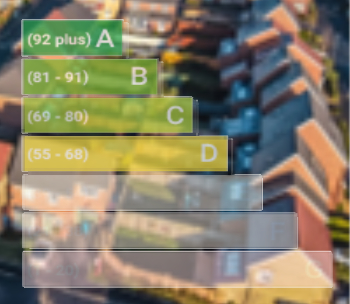

Warm Homes Plan and existing energy bill support policies

Breaking down what existing policies are and what they do.

Treasury responds to sector submission on Warm Homes

Trade associations call on Government to make good on manifesto pledge for the upgrading of 5 million homes.

A tour through Robotic Installation Systems for Elevators, Innovation Labs, MetaCore and PORT tech.

A dynamic brand built for impact stitched into BSRIA’s building fabric.

BS 9991:2024 and the recently published CLC advisory note

Fire safety in the design, management and use of residential buildings. Code of practice.